Robert Knott & Stephen Lilley

With the UK electricity network undergoing a rapid increase in size to help accommodate new green generation facilities, bespoke earthing system design and earth fault studies are required to ensure compliance of these sites with UK regulations. As per Health and Safety Executive (HSE) legislation [1], the installation of earthing systems is a legal requirement within the UK to ensure safety of people operating within or on a system that may reasonably become charged as a result of either the use of a system, or a fault in a system. Earthing systems are key in ensuring that during abnormal events on the system, persons and assets are sufficiently protected.

Importance of earthing systems

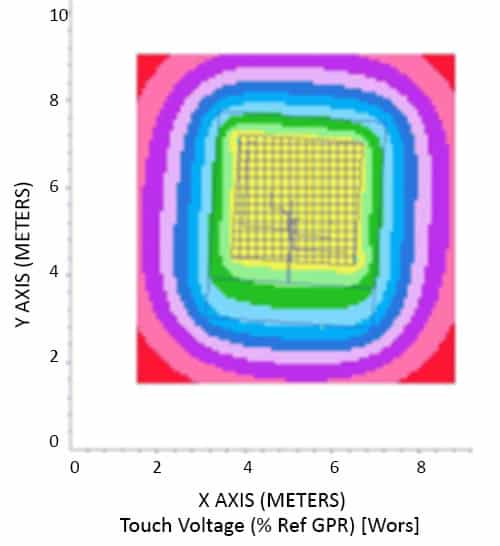

Secondly, implementing a compliant earthing system can reduce the impact of earth potential rise (EPR) upon sensitive equipment, HV plant and expensive site infrastructure that may be at risk of damage during earth fault conditions on a system. Earth potential rise occurs on an earthing system (typically during an fault condition), where current flowing through the earth causes a difference in potential between a point on the ground and a remote earth, such as a connected item of HV equipment.

Finally, the calculated EPR will cause surface potentials to extend past the exent of the site boundary. Dependant upon the EPR, these surface potentials may cuase hazards present upon third-party systems such as Communication Network Providers (CNP) systems [3], pipelines [4] or domestic LV systems [5].

Aspects of HV earthing design

Although a complex study, earthing – as well as many studies within the power sector – comes down to Ohms law. The EPR experienced at a HV plant or site is calculated from the single phase to earth fault current and the designed earthing system impedance. Therefore, by either reducing the overall earth impedance of a site (through detailed earthing design studies) or the fault current through calculation of the ground return component, or both, the EPR may also be significantly reduced. It is the EPR that subsequently determines the touch or step voltages experienced at a site or the impact upon third-party infrastructure or people.

Earthing system design can be challenging, particularly with sites fed by unearthed overhead lines and with limited land availability to install copper, such as 11kV EV charger substations. The impact of soil resistivity upon earthing system design cannot be ignored either, creating a reliable and accurate representation of the soil where the electrode will be laid is key in calculating the earth impedance. The characteristics of the soil model will also have important effects on touch potentials and surface potentials seen under fault conditions.

As a result, bespoke earthing designs are necessary, which considers the soil resistivity, land availability, supply arrangement, and surrounding network, to create safe systems and ensure compliance with UK and international standards.

How PSC can help

PSC has developed effective modeling and analysis techniques to provide customized, safe and compliant earthing system designs efficiently.

We support our clients from pre-construction through the design process and post-construction commissioning phases of any project.

Learn more about our capability in this area or contact us to find out how we can help you.

References

| [1] | The Electricity at Work Regulations 1989, HSR25, Third Edition, 2015, Published by Health and Safety Executive. |

| [2] | ENA Technical Specification 41-24, “Guidelines for the Design, Installation, Testing and Maintenance of Main Earthing Systems in Substations”, Issue 2, November 2018, published by Energy Networks Association. |

| [3] | ENA Engineering Recommendation S36, “Identification and recording of ‘hot’ sites – joint electricity industry and Communications Networks Providers”, Issue 2, 2018, published by Energy Networks Association. |

| [4] | BS EN 50443:2011, “Effects of electromagnetic interference on pipelines caused by high voltage a.c. electric traction systems and/or high voltage a.c. power supply systems”, 2011, published by British Standards Institute. |

| [5] | ENA ER S41, “Guidance on transferred voltages from earthing systems”, 2021, published by Energy Networks Association. |

| [6] | CDEGS (Current Distribution, Electromagnetic Fields, Grounding and Soil Structure Analysis). SES & technologies Ltd, 3055 Boulevard des Oiseaux, Laval, QC H7L 6E8, Canada. |