As the world accelerates its transition to a low-carbon economy, offshore wind farms have become an important element of the strategy to meet global net-zero targets. To effectively transmit the vast amounts of energy generated by offshore wind turbines, a dedicated substation platform is required and as a key component of this power network, a robust earthing system is essential to ensure the safety of the platform and its operations. In this article, we discuss the challenges and solutions to modeling earthing systems in marine environments.

The Challenge of Earthing in the Offshore Environment

The design of earthing systems for offshore installations presents unique and significant challenges. Within the industry, global standards and policies are primarily catered to onshore systems and do not adequately consider the unique characteristics of high-voltage systems surrounded by large bodies of water.

The main challenges associated with designing these systems include accurately modeling their performance in a highly conductive saltwater environment, which affects the dissipation of fault currents. Furthermore, there are significant practical difficulties with the installation of large-scale earthing electrodes in deep water, often contending with strong underwater currents and the complex geology of the seabed. Mitigating corrosion is also paramount, as the highly corrosive marine environment can rapidly degrade earthing components, often requiring the integration of cathodic protection systems.

The absence of specific international standards means that designs must be rigorously verified to ensure the safety of personnel and the reliable operation of the electrical system.

Key Design Considerations for Offshore Earthing Systems

Designing earthing systems for offshore installations is a complex engineering challenge that moves beyond conventional onshore practices. The core principle is to harness the large, highly conductive body of saltwater and the steel structure of the platform itself as the primary earthing electrode. This requires a holistic approach that integrates three key design considerations.

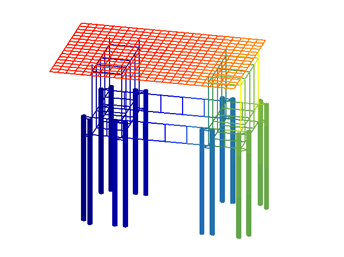

First, the platform’s substructure and piles, which are in direct contact with the seabed, are leveraged as an incredibly effective, low-impedance earth. Sophisticated modeling, using software such as the SES CDEGS HiFREQ module, is essential to determine how this large-scale system will dissipate fault currents and to ensure that hazardous step and touch potentials remain within safe limits.

Second, the design must prioritize corrosion mitigation. The hostile marine environment necessitates the use of corrosion-resistant materials and potentially, the application of cathodic protection (CP) systems to protect the steel structure. The earthing system must be carefully integrated with the CP system to prevent stray currents and galvanic corrosion, safeguarding the integrity of the entire platform.

Finally, safety and redundancy are paramount. The system must be designed to safely manage high-magnitude fault currents, while ensuring that all metallic components are equipotentially bonded. This comprehensive approach, which combines electrical, structural, and corrosion engineering, is vital for creating a robust and safe offshore earthing system that can withstand the unique demands of the marine environment.

The Vital Role of Accurate Modeling in Offshore Safety

Figure 1 – CDEGS HiFREQ Model of an offshore platform Figure generated by CDEGS (produced by SES & Technologies)

The safety of personnel and the longevity of high-voltage offshore assets depend entirely on the predictability of the earthing system. Industry standard onshore earthing processes do not account for the high conductivity of saltwater or complex seabed geology and so accurate modeling is the only way to ensure that fault currents dissipate safely. Without rigorous verification through sophisticated software like SES CDEGS, installations risk hazardous step and touch potentials that threaten human life and equipment integrity.

By investing in advanced earthing analysis during the design phase, clients can:

- Ensure Regulatory Compliance: Navigate the absence of specific international offshore standards with rigorously verified designs that meet global safety expectations.

- Protect Assets and Personnel: Mitigate the risk of catastrophic electrical failure and rapid structural degradation due to corrosion.

- Optimize Operational Continuity: Avoid the prohibitive costs of retrofitting earthing electrodes in deep-water environments by getting the design right the first time.

Why Partner with PSC?

PSC is uniquely positioned to bridge the gap between complex marine environments and robust electrical engineering. Our approach leverages:

- Specialized Expertise: Our team understands the interplay between electrical, structural, and corrosion engineering required for offshore success.

- Advanced Toolsets: We utilize the industry-leading SES CDEGS HiFREQ module to create high-fidelity models of platform substructures and piles, ensuring accurate predictions of fault current dissipation.

- Bespoke Solutions: We deliver tailored designs that integrate earthing with cathodic protection (CP) systems, safeguarding your installation from stray currents and galvanic corrosion.

Contact our specialist team to learn more.